PU leather is called polyurethane leather, which is a synthetic leather made of polyurethane material. Pu leather is a common leather, widely used in a variety of industry products, such as clothing, footwear, furniture, automotive interior and accessories, packaging and other industries.

Therefore, pu leather occupies a very important position in the leather market.

From the production process and environmental protection concept, pu leather is mainly divided into two kinds of recycled pu leather and traditional pu leather.

What is the difference between the two kinds of leather?

Let’s first look at the differences in their production processes.

Traditional pu leather production process:

1. The first step in the production of pu leather is to make polyurethane, and the isocyanate (or polyol) and polyether, polyester and other raw materials are made into polyurethane resin through chemical reaction.

2. Coating the substrate, polyurethane resin coated on the substrate, as the surface of pu leather, the substrate can be selected a variety of textiles, such as cotton, polyester cloth, etc., or other synthetic materials.

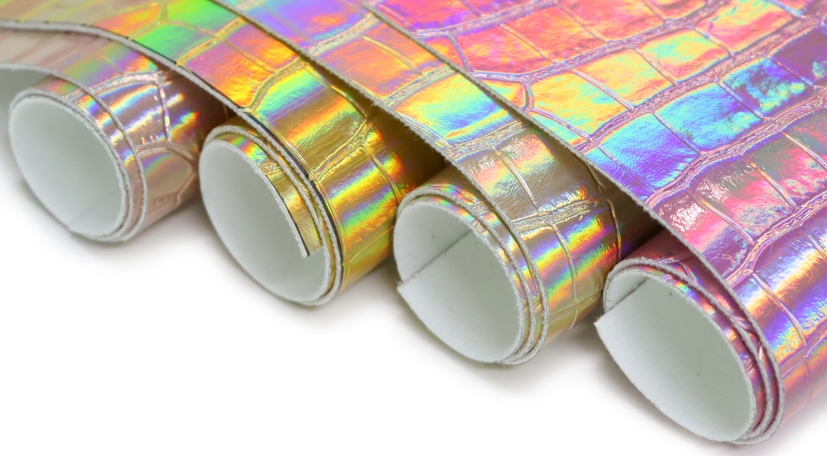

3. Processing and treatment, the coated substrate is processed and treated, such as embossing, printing, dyeing and other processes, in order to obtain the required texture, color and surface effect. These processing steps can make PU leather look more like real leather, or have a specific design effect.

4. Post-treatment: After finishing processing, PU leather may need to undergo some post-treatment steps, such as coating protection, waterproof treatment, etc., to enhance its durability and characteristics.

5. Quality control and testing: In all stages of production, quality control and inspection will be carried out to ensure that PU leather meets the design and specification requirements.

The production process of recycled pu leather:

1. Collect and recycle waste polyurethane products, such as old pu leather products, production waste, after sorting and cleaning surface impurities and dirt, and then do drying treatment;

2. Pulverize the clean polyurethane material into small particles or powder;

3. Use a mixer to mix polyurethane particles or powders with polyurethane prepolymers, fillers, plasticizers, antioxidants, etc., and then put them into the heating equipment for chemical reaction to form a new polyurethane matrix. The polyurethane matrix is then made into a film or specified shape by casting, coating or calendering.

4. The formed material is heated, cooled and cured to ensure physical properties and chemical stability.

5. Cured recycled pu leather, embossed, coated, dyed and other surface treatment to obtain the desired appearance and texture;

6. Conduct quality inspection to make it meet relevant standards and requirements. Then according to customer requirements, cut into different sizes and shapes of finished leather;

Through the production process, it can be understood that compared with traditional pu leather, recycled pu leather pays more attention to environmental protection and resource recycling, reducing environmental pollution. We have GRS certificates for pu and pvc leather, which cater to the concept of sustainable development and environmental protection, and practice in leather production.

Post time: Jun-25-2024